CONIFY Powder

About us

CONIFY’s main activities involve the revitalization, upcycling and recycling of unfused/low-cost powders, not meant for Additive Manufacturing (AM) towards high-quality AM-compatible powders. In such a way CONIFY tries to link production chain from 3D printing and post-processing wastes back to design and printing. The company gathers required expertise to provide a high-quality environment for the development and demonstration of new alloy compositions based on novel metal alloy design approaches.

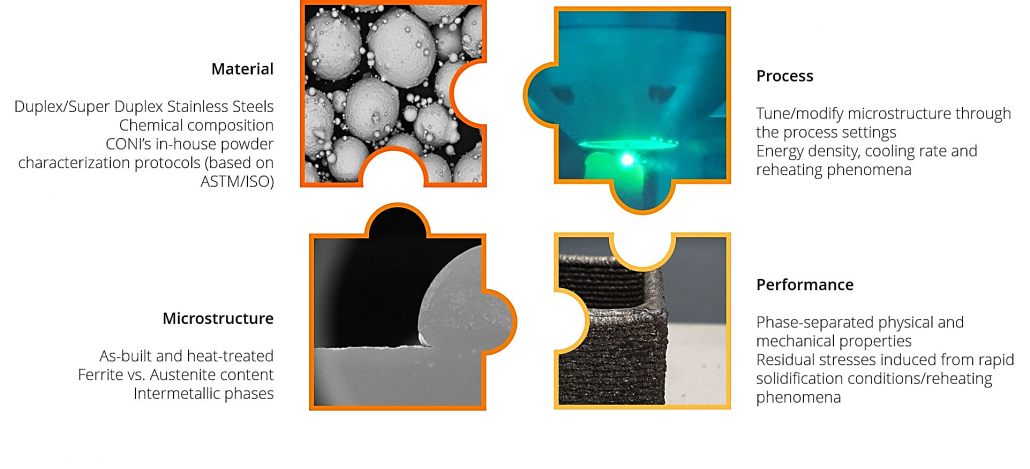

CONIFY brings into the current project its AM toolbox comprising of;

- raw material procurement and assessment tools, ranging from low-cost powders not intended for AM, unfused AM powders, and machining waste or recovered metals from industrial waste to commercially available AM powder feedstock

- in-house testing and precise physico-chemical material characterization according to ISO and ASTM methods, for quality-controlled AM-powders,

- dedicated, case-by-case adapted post-processing procedures and metal alloy design approaches are developed towards AM powders of high-quality standards and

- 3D printing activities and parametric studies to design and optimize our manufacturing processes in order to achieve print-tested, validated powdered materials, combined with microstructural and mechanical characteristics of the final parts. The team specializes in Laser-Powder Bed Fusion (LPBF) applications and Direct Energy Deposition (DED) processing while continuously pushing the frontier of AM manufacturing for more demanding applications (e.g., aerospace).